Atago combines the function of a high-performance fire-block material used in aircraft cushion assembly, with the aesthetic appearance of a dress cover material into one complete solution. This groundbreaking technology reduces the number of components required, without sacrificing the style or performance.

Saves up to 0.75lbs per seat!

For more information on Atago for aviation, click here to contact European Sales Director, Richard Field

- Protection That Lasts

Utilizing an inherent, bonded process, fire resistance is integral to Atago’s structure. It can be cleaned countless times with the confidence that the fire resistance will not degrade.

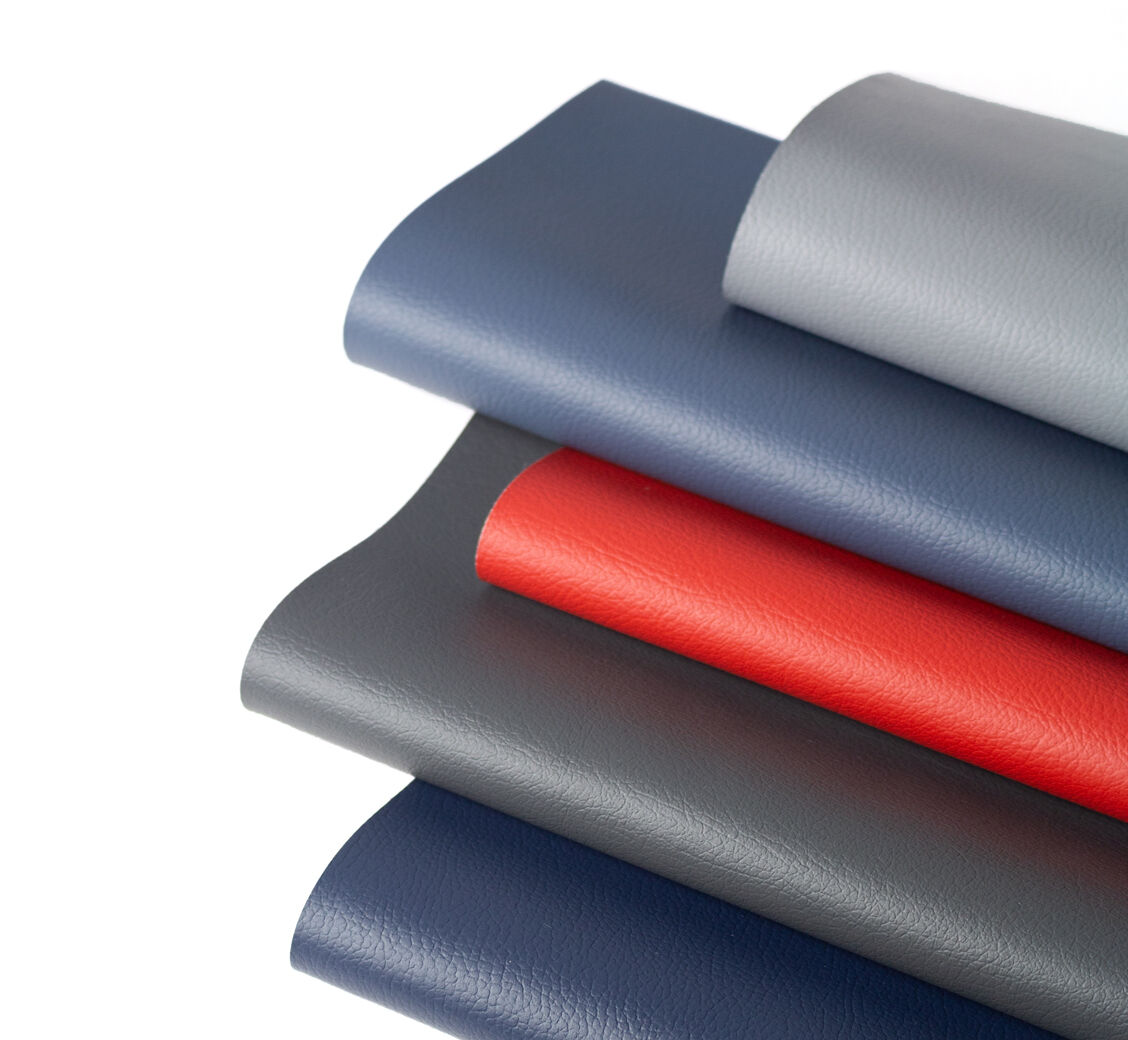

Manufactured using Ultrafabrics' proprietary technology, Takumi Technology, Atago incorporates high resistance against abrasion, flexing and hydrolysis whilst retaining a luxurious touch.

Atago is engineered with an EPA-registered antimicrobial agent which has been constructed to inhibit the growth of bacteria and other surface pathogens.

- Lightweight & Durable

From thinner glassware to redesigned meal trays or lighter catering equipment, airlines are constantly looking for ways to reduce weight

As seating platforms become more complex, finding lightweight and easily certified solutions becomes a challenge. Atago solves this challenge with its unbeatable haptics, inherent flame retardancy and performance attributes, while providing never-before-seen weight savings!

- More on Atago

Atago is named after the Atago Shrine in Tokyo, Japan which was built to protect the residents from fire.

• Lowering fuel consumption and emissions

• Reducing manufacturing cycle time

• Decreasing time and risk in burns testing

• Allowing older 14G cushion constructions to meet current FR requirements safely